- Power supply temp monitor how to#

- Power supply temp monitor software download#

- Power supply temp monitor full#

- Power supply temp monitor Pc#

- Power supply temp monitor series#

More sensors can be purchased seperately, if needed. *As standard two temperature sensors are included. temperature sensor, 5m cable (4-wire), with plug temperature sensor, 3m cable (4-wire), with plug Top benefits of power monitoring Condition monitoring strengthens your maintenance and reliability program by: Examine single, split, and three phase systems Examine voltage, current, and frequency from electrical systems to detect mechanical problems or component wear in assets.

Power supply temp monitor series#

Power supply temp monitor how to#

By adding the oil level & temperature monitor from Spica Technology, you can get a warning before a temperature or a level gets critical.ĭue to the magnets on the backside of the module, the level monitor can easily be mounted anywhere on a metal/iron surface.

Power supply temp monitor software download#

MT300 Monitor Software Download Version 2.Low levels and high temperatures are often reasons for unplanned stops. (Use only if the newer version 2.0 below doesn't work on your system) Everything you need to start remotely monitoring temperature Quick, easy set up straight out of the box View data online via web browser Download data for. MT300 Monitor Software Download Version 1.0

Power supply temp monitor full#

Power supply temp monitor Pc#

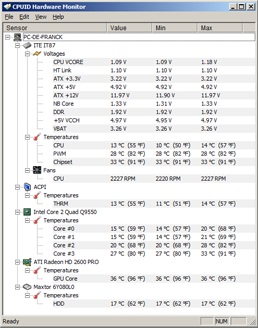

Configurable through the front-panel interface, MODBUS over USB or the isolated RS-485, PC software included for data logging and configuration How to Monitor Power Supply Temperature PSUs are not equipped with an inbuilt temperature monitor.Universal inputs of 1 Ω platinum RTDs and Types E and K thermocouples.Key features of micro-processor-based temperature monitor: The monitor is easily configured via MODBUS over a USB connection to your PC or MODBUS/RS-485 using the included PC software that also provides data logging. The user-configurable fan exercise option extends the fan life and reduces bearing lock-up. Additionally, one of the relay outputs is specifically designed for control of a cooling fan with a 30 Amp rating. The microprocessor-based design maintains accuracy over a wide range of temperatures and conducts regular self-checks to ensure correct operation. The MT300 provides users a completely programmable transformer temperature monitor and alarm with improved measurement range of -50☌ to 300☌ (-58☏ to 572☏) and universal inputs of either 100Ω or 1000Ω Platinum RTDs or Types E or K thermocouples.

0 kommentar(er)

0 kommentar(er)